PESP Plastic Steel Composite Pipe Production Line

PESP Plastic Steel Composite Pipe Production Line

The perforated steel belt plastic pipe produced by our company can be divided into: water supply, buried gas, hot water, chemical industry and special use.

Perforated steel belt polyethylene composite pipe is reinforced by the welded hole network of cold-rolled steel belt, and composite thermoplastic composite pipe. Due to the introduction of reinforced skeleton, the compressive strength of the pipe is significantly improved. The selection of different types and brands of thermoplastic can produce composite pipes of different uses.

The perforated steel belt plastic pipe produced by our company can be divided into: water supply, buried gas, hot water, chemical industry and special use.

(dn)/mm Nominal Diameter | Thickness | Nominal Pressure/Mpa | Weight(m/kg) | Length(m) | |

Water Supply | Gas | ||||

50 | 4.0 | 2.0 | 1.0 | >1.4 | 6、9、12 |

63 | 4.5 | 2.0 | 1.0 | >2.0 | 6、9、12 |

75 | 5.0 | 2.0 | 1.0 | >2.5 | 6、9、12 |

90 | 5.5 | 2.0 | 1.0 | >3.5 | 6、9、12 |

110 | 6.0 | 2.0 | 1.0 | >4.6 | 6、9、12 |

140 | 8.0 | 1.6 | 1.0 | >7.1 | 6、9、12 |

160 | 10.0 | 1.6 | 1.0 | >8.7 | 6、9、12 |

200 | 11.0 | 1.6 | 1.0 | >11.7 | 6、9、12 |

225 | 11.5 | 1.6 | 1.0 | >16.5 | 6、9、12 |

250 | 12.0 | 1.6 | 0.8 | >20.5 | 6、9、12 |

280 | 12.5 | 1.6 | 0.8 | >23.9 | 6、9、12 |

315 | 13.0 | 1.25 | 0.8 | >26.6 | 6、9、12 |

355 | 14.0 | 1.25 | 0.8 | >32.6 | 6、9、12 |

400 | 15.0 | 1.25 | 0.8 | >39.3 | 6、9、12 |

450 | 16.0 | 1.25 | 0.8 | >45.7 | 6、9、12 |

500 | 18.0 | 1.25 | 0.8 | >52.8 | 6、9、12 |

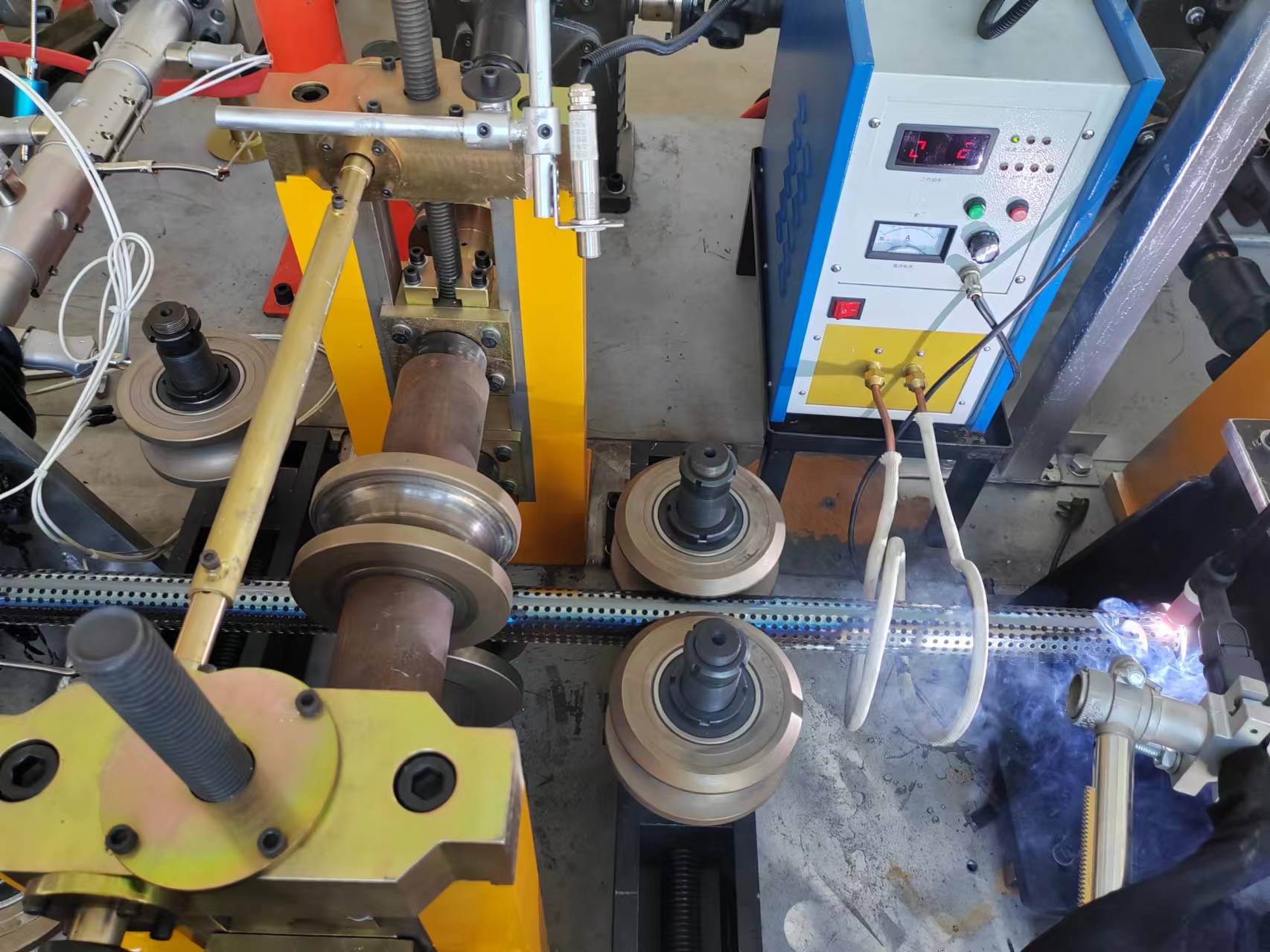

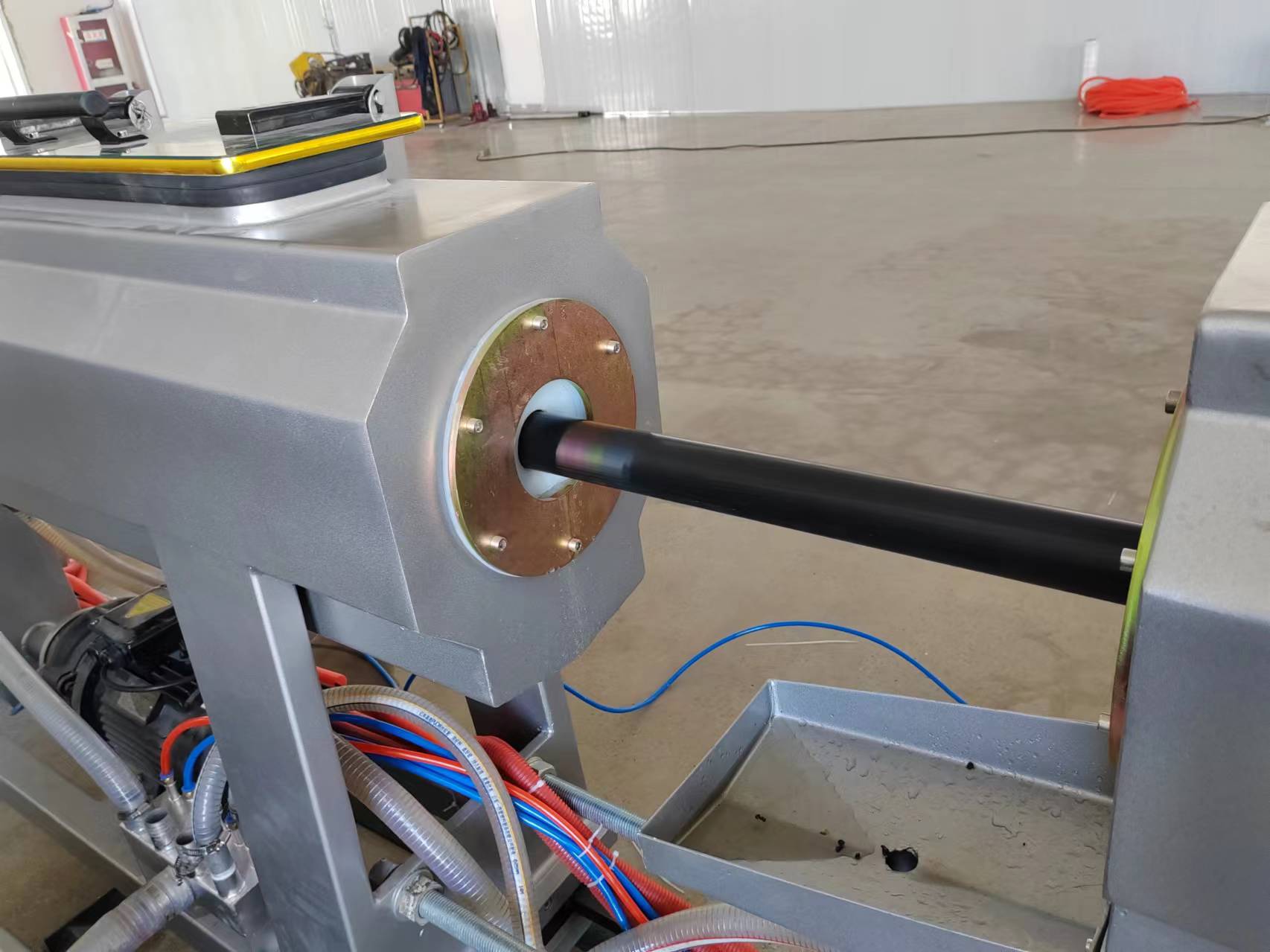

This is our new Perforated steel PE composite pipe production line.The pipe diameter range is ø50-630mm. The production process is : Firstly, holes are punched on the thin steel strip, and the steel strip is formed into a circular steel pipe by pipe forming machine and argon arc welding. The plastic material is then covered to the inner and outer layers of the steel pipe by a plastic extruder, and the outer and inner layers of the plastic are connected through the holes in the steel pipe by extrusion. The resulting pipe, plastic and steel, have become a whole, no layering or detaching.

Equipment features: It’s adopted precision roll forming technology to ensure the stability of steel strip forming and welding; the production line adopts advanced touch screen and PLC control, single machine adjustment, whole line linkage, high degree of automation, stability and reliability.